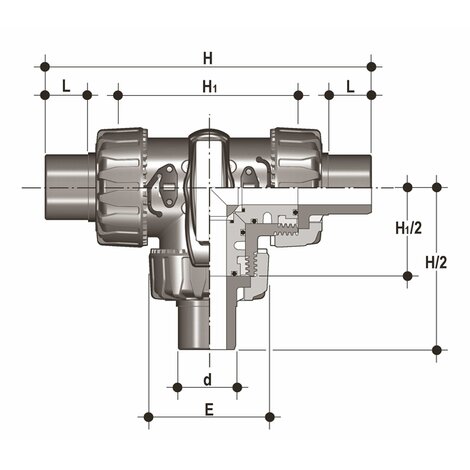

TKDDM - DUAL BLOCK® 3-way ball valve DN 15:50

DUAL BLOCK® 3-way ball valve with male ends for socket welding, metric series, T-port ball.

FIP has developed a TKD DUAL BLOCK® ball valve to introduce a high reference standard in thermosplastic valve design. TKD is a True Union diverting and mixing ball valve that meets the most stringent needs required in industrial applications.

Main features:

- Ergonomic HIPVC handle equipped with removable tool to adjust the ball seat carrier. Possibility of installing the LTKD stroke limiter (available as an accessory) that permits ball and handle rotation only for set opening and closing angles at 90° or 180°

- Handle lock 0°- 90° SHKD (available as an accessory) ergonomically operable during service and padlockable

- DUAL BLOCK® patented lock system that ensures union nut tightening hold even in severe conditions such as vibrations or heat dilation

- Ball shutter high surface finish with floating type full passage with T or L port

- 4 PTFE ball seat system that compensates axial force guaranteeing optimal manageability and long working life

EPDM

| Reference | H | d | DN | g |

|---|---|---|---|---|

| TKDDM020E | 140 | 20 | 15 | 205 |

| TKDDM025E | 175 | 25 | 20 | 360 |

| TKDDM032E | 188 | 32 | 25 | 515 |

| TKDDM040E | 220 | 40 | 32 | 835 |

| TKDDM050E | 251 | 50 | 40 | 1100 |

| TKDDM063E | 294 | 63 | 50 | 1830 |

FKM

| Reference | H | d | DN | g |

|---|---|---|---|---|

| TKDDM020F | 140 | 20 | 15 | 205 |

| TKDDM025F | 175 | 25 | 20 | 360 |

| TKDDM032F | 188 | 32 | 25 | 515 |

| TKDDM040F | 220 | 40 | 32 | 835 |

| TKDDM050F | 251 | 50 | 40 | 1100 |

| TKDDM063F | 294 | 63 | 50 | 1830 |

- Connection system for weld and threaded joints

- Patented SEAT STOP® ball seat carrier system that lets you micro-adjust ball seats and minimise axial force effects

- Easy radial disassembly allowing quick replacement of O-rings and ball seats without any need for tools

- PN10 True Union valve body made for PP-H injection moulding equipped with built-in bores for actuation. ISO 9393 compliant test requisites

- Option of disassembling downstream pipes with the valve in the closed position

- High surface finish stem with double O-Ring and double groove ball connection, equipped with optical position indicator for correct handle installation

- Integrated bracket for valve anchoring

- Possibility of installing pneumatic and/or electric actuators thanks to the robust integrated bracket for valve anchoring for easy and quick automation using the Power Quick module (optional)

- Possibility to have handle with integrated LSQT limit micro switch, even as a retrofit in existing installations

get_app

get_app