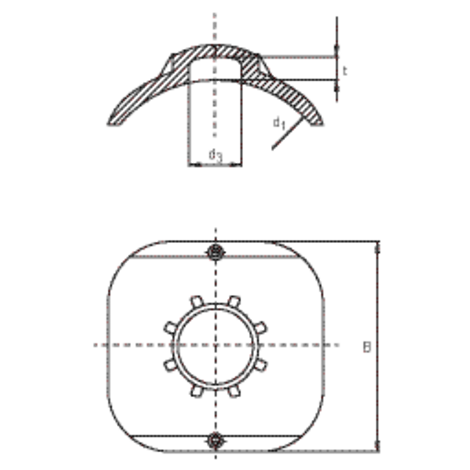

Repair saddle for top loading, SDR11

Repair saddle Top-Loading RS TL SDR 11

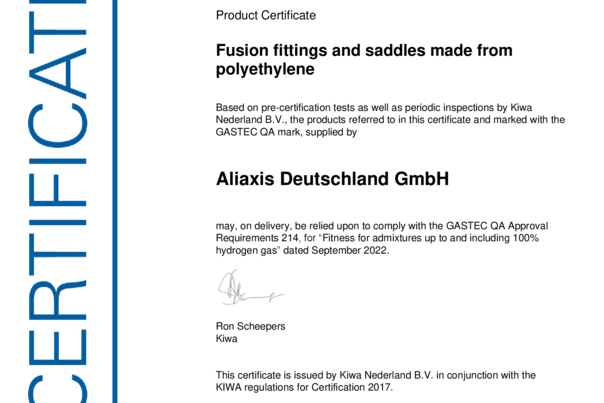

- Gas, water and H2

- Working pressure: MOP (gas) 10 bar, PFA (water) 16 bar

- Material: PE 100

- Universal clamping option (top loading):

- Safe clamping with FRIATOP

- Universal adaptation to pipe diameter

- Safety technology

- DVGW test mark: DV-8611AU2250

Note:

Can only be used with the clamping device FRIATOP (Order No. 613350).

Only apply to minor pipe damage.

The damage must be located within the repair area and not in the fusion zone.

PE 100 SDR 11

Maximum permissible working pressure 16 bar (water) / 10 bar (gas)

| Reference | d1 | d3 | B | t | Weight [kg] | BX | PU |

|---|---|---|---|---|---|---|---|

| 615397 | 250-560 | 50 | 200 | 20 | 0,580 | 10 | 180 |

FRIALEN safety fittings can be fused with SDR levels 11 to 17.6. Other levels of SDR can be processed on request. Please note the mandatory labels directly on the product. DVGW test marks issued: DV-8611AU2250

Areas of Application

The FRIALEN-Repair Saddle Top-Loading VSC-TL is used for the repair of minor pipe damages with and without discharge of media.

Assembly Instructions

The saddle is suitable for all pipe diameters in the given range. It is clamped onto the pipe by means of the FRIATOP clamping unit (see product range “Technical Equipment”). Please read the “Assembly and Operating Instructions for FRIATOP Clamping Unit (Top-Loading)”.

The fusion of the HD-PE distribution pipes with the FRIALEN-Repair Saddle takes place by FRIALEN-fusing – leakproof and longitudinally strong.

In order to avoid discharge of media, the leak has to be sealed with a separate plug (≤ d3).

The pipe and the saddle have to be prepared according to the general installation instructions (see “Assembly Instructions” for “FRIALEN-Special Technology for laying large bore pipes and relining pipe networks ≥ d 250”). This involves removing the oxide layer and cleaning the pipe covered by the saddle.

Good reasons for using the FRIALEN Repair saddle for top loading:

- Compact construction

- HD-PE saddle with exposed heating element for optimal heat transfer

- Sealing area free of heating wires

- Extra wide fusion zone

- The VSC-TL can be applied universally to large HD-PE pipe diameters d 250-560. This means additional economy since less material is needed and less stock at both suppliers and trade is necessary.

- Additional barcode for tracing back the fitting (Traceability-Coding)

Downloads

Accessories

get_app

get_app

get_app

get_app