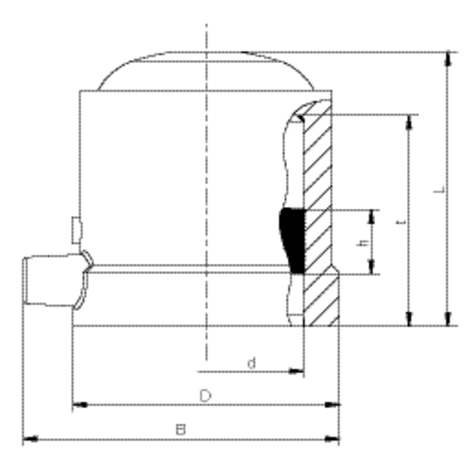

Cap for tapping tees, SDR 11

Cap for tapping tees DK SDR 11

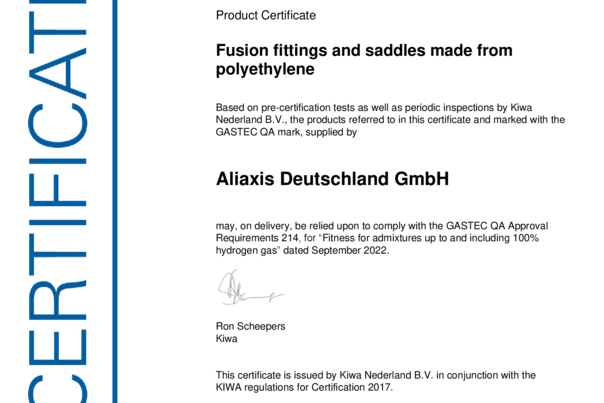

- Gas, water and H2

- Working pressure: MOP (gas) 10 bar, PFA (water) 16 bar

- Material: PE 100

- Safety technology

- DVGW test mark: DV-8601AU2248

PE 100 SDR 11

Maximum permissible working pressure 16 bar (water) / 10 bar (gas)

| Reference | d | B | D | h | t | Weight [kg] | BX | PU |

|---|---|---|---|---|---|---|---|---|

| 612310 | 50 | 82 | 69 | 28 | 55 | 0,120 | 30 | 960 |

FRIALEN safety fittings can be fused with pipes with SDR levels 11 to 17.6. Minimum wall thickness s minimum ≥ 3 mm. Other levels of SDR can be processed on request. Please note the mandatory labels directly on the product. DVGW test mark issued: DV-8601AU2248

Areas of Application

The FRIALEN-Cap is used for final sealing of the drill socket (dome) of a Pressure Tapping Tee DAA ≥ d 90/xx or SPA d 63. Also suitable as a sealing cap for d 50 pipes.

Assembly Instructions

The fusion of the dome of a FRIALEN-Pressure Tapping Tee with the FRIALEN-Cap K takes place by FRIALEN-fusing – leakproof and longitudinally strong.

The dome is prepared according to the general installation instructions (see “Assembly Instructions” for “FRIALEN-Safety Fittings for house connections and distribution pipes up to d 225”).

Good reasons for using the FRIALEN-Cap DK:

- Large insertion depth for ease of pipe guiding

- Maximum stability through great wall thickness

- Cold zones at the end to prevent the flow of molten material

- Exposed heating coils for optimal heat transfer to the pipe

- Small annular gap for build-up of optimum joining pressure in the fusion zone

- Contacts safe to touch

- Durable batch marking

- Individually wrapped for dirt protection

- Additional barcode for tracing back the fitting (Traceability-Coding)

get_app

get_app

get_app

get_app